One of the major technical milestones for us was to design a system that would reliably and accurately deposit the correct quantities of heated vegetable oil on demand – i.e. spraying the weeds while leaving keeper crops unharmed in the seedline.

UC Davis research on thermal micro-dosing found that weeds within the seedline in processing tomato fields could be successfully treated with lethal doses of heated vegetable oil, providing a herbicide-free method of weed control which doesn’t rely on costly hand labor. Our task was to design a system that could scale for continuous usage while retaining tight control of parameters such as deposition rate and oil temperature.

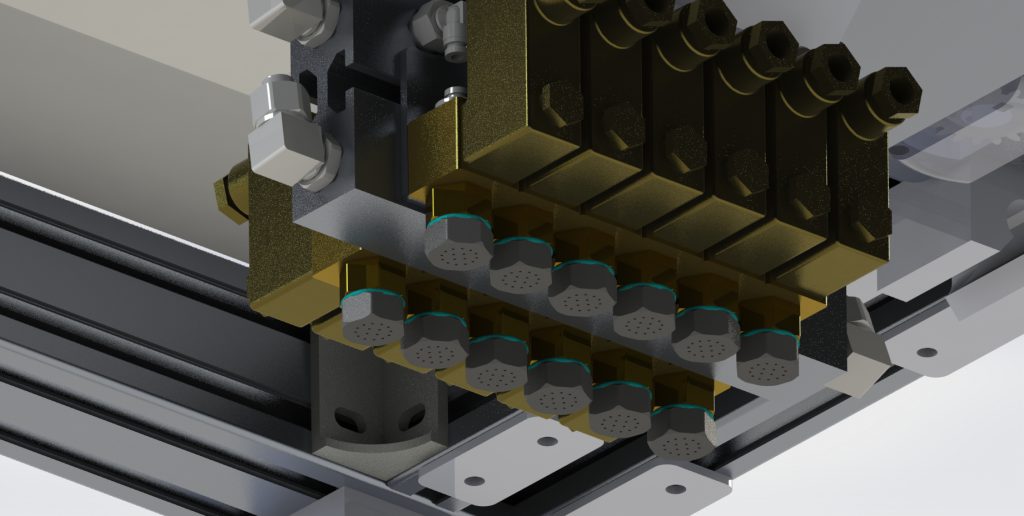

The main technical challenges here were i) to implement controlled heating in the system all the way through to the nozzles ii) to regulate pressure without a recirculating system which would degrade the oil iii) to design a nozzle that accurately sprayed and wouldn’t drip and iv) to design solenoid driver electronics that maximized the effective speed of the system

This is where the huge advantages of being plugged into Shenzhen’s hardware ecosystem through our connections with SOSV/HAX came in. Within a month, we had design concepts sketched up and ready to test, using a combination of available off-the-shelf components (such as the hydro-pneumatic cylinder plus cartridge mold heaters to regulate oil pressure and temperature) and custom-machined parts for the oil deposition system from local factories.

Drip-testing a number of different nozzle designs was one of the first tasks. Having a side-by-side setup of two nozzles allowed us to test many competing designs against each other over the course of several months:

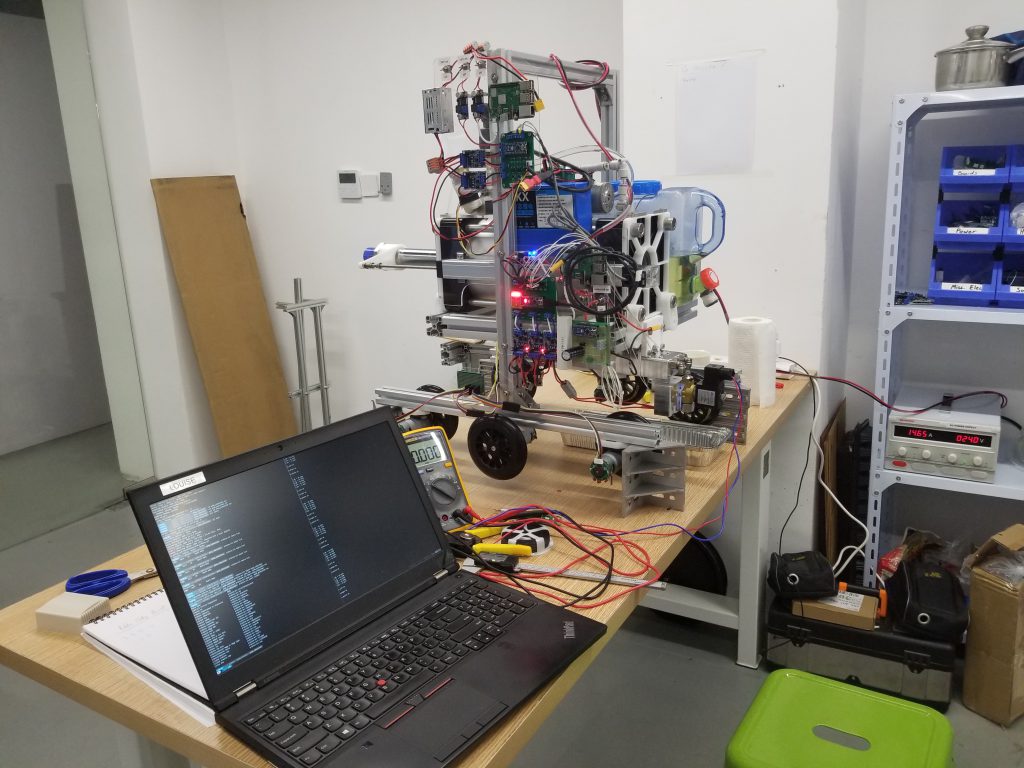

Once we had settled on a design for accurate anti-drip placement of oil, we needed to work on the driver electronics and solenoid valve selection to ensure we would be able to dose weeds at real-world speeds.

The accuracy and repeatability of our oil deposition system was assessed with our test rig (we’ve named it Gatling – sound on below for explanation). The results below show consistent dosing of heated oil without dripping.

Key features and learnings of these rough-and-ready prototypes have been carried across to our final design implementation for deployment.